System Accessories

System accessories refer to equipment incorporated into a process cooling system design. These accessories will supplement the system to improve its operation and extend its productive lifespan. Thermal Care’s experts can select and incorporate the appropriate accessories recommended for your specific system.

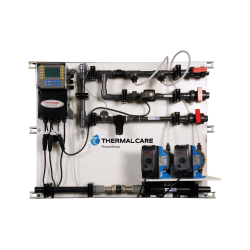

Water Treatment Systems are a simple solution used in conjunction with a local water treatment specialist to address naturally occurring issues associated with cooling system water. This is especially important for cooling tower systems. Cooling tower systems are more susceptible to scale, suspended solids and microbiological growth. Water Treatment Systems are a key component to implementing a proper preventive chemical treatment schedule.

Additional Information

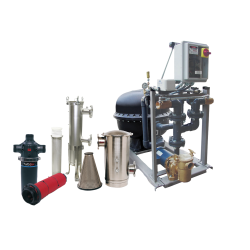

Protecting the equipment in your system is extremely important. Physical debris in the system can be introduced in a variety of ways and can have a detrimental impact on the system’s operation. A primary line of defense against this is physical filtration equipment. Thermal Care offers a wide variety of filtration options. These range from small cartridge or bag filters installed on pumping systems as side stream filters to stainless steel strainer/filters designed for full system flow up to 1,000 gpm per unit. All of these filtration options are designed to have minimal impact on the system’s operation while providing reliable protection for the processing equipment supported by the cooling system.

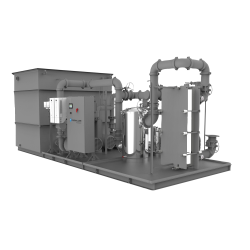

Another common accessory used with a process cooling system is a heat exchanger. Heat exchangers are a specialized piece of equipment designed to isolate one fluid from another while still allowing energy to be transferred between them. This is important when the two fluids are different and cannot mix, when one fluid is dirty or contaminated, or when one requires special chemicals like glycol. Heat exchangers are a crucial part of many systems and can be shipped loose to be incorporated in the field installed piping or can be integrated into the Thermal Care equipment at the factory. Heat exchangers are available in a variety of designs and configurations. The experts at Thermal Care can help to determine the necessary design conditions and ensure the heat exchangers are properly incorporated into the requirements of your system.

Have Any Questions?

This unit will consume less than half of the energy than the unit it replaced," Nakari said. "It's providing our molds with more stable cooling, which translates to less manufacturing variability and better process quality. Plus it gives us the ability to expand as we add additional presses in the future." Nakari said Intertech believes it will save approximately $40,000 in energy costs as a result of this investment. Tim Nakari, Intertech Plastics Inc. (Taken From Plastics News Today)