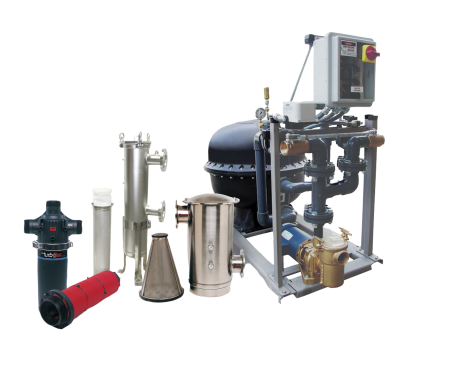

Filtration Equipment

Protecting the equipment in your system is extremely important. Physical debris in the system can be introduced in a variety of ways and can have a detrimental impact on the system’s operation. A primary line of defense against this is physical filtration equipment. Thermal Care offers a wide variety of filtration options. These range from small cartridge or bag filters installed on pumping systems as side stream filters to stainless steel strainer/filters designed for full system flow up to 1,000 gpm per unit. All of these filtration options are designed to have minimal impact on the system’s operation while providing reliable protection for the processing equipment supported by the cooling system.

BF Series Bag Filters

Used on tower and/or chilled water applications where full flow filtration is required. One-piece assemblies have a removable lid and stainless steel filter supports. The 60 mesh, reusable, woven polypropylene filter bag is designed to have less than one psi pressure drop. A single housing can filter up to 300 gpm and modular designs are available for any flow requirement. Available with steel or stainless steel housing.

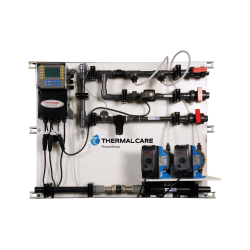

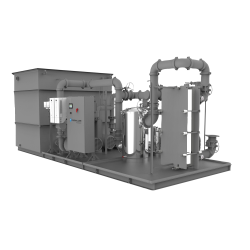

PS Series Sand Filters

Completely assembled with a FRP housing, appropriately sized pump and automatic backwash valves. Units are easy to install as equipment comes mounted to a structural steel base with all electrical controls in a NEMA 3R control panel. Automatic backwash feature conserves water as backwash frequency is determined by water pressure not time interval. Used for side stream removal of suspended solids, five microns and larger. Flow rates from 45 to 100 gpm.

TD Series Turbo Disc Filters

Ideal for well water make-up lines, extrusion lines for full flow filtration, or for small tower or chiller systems. Filters contain reusable, 3-dimensional polypropylene discs compressed together to remove particulate. A helix located at the base of the cartridge spins incoming water, keeping heavier particulate in suspension — blackflush frequency is minimized. Filtered debris collects in the exterior of disc stack and across depth of discs.

SF Series Screen Filtration

Unique stainless steel filter vessel with a patented conical stainless steel filter screen design to provide up to 200 mesh filtration, filtering a flow rate of 100 to 2000 gpm with less than one psi pressure drop. Units come standard with inlet and outlet pressure gauges for fast and easy filter monitoring.

Optional package electronically monitors pressure and purges reservoir. When the pressure differential increases, contaminant is easily flushed out of the filter by opening the flush line valve. Standard screen is 60 mesh for cooling tower systems and 100 mesh for central systems.