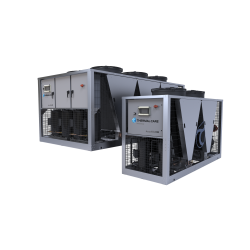

50 to 500 Ton MX Series Rotary Screw Compressor Chillers

50 to 500 ton

MX Series industrial central chillers use a compact rotary screw compressor for greater reliability, energy efficiency and noise reduction. Each independent refrigeration circuit contains a brazed plate evaporator for greater chiller reliability and features a powerful controller to monitor, control and maintain stable and reliable operation of the chiller.

MX Series chillers now come standard with Dynamic Lift Technology to continuously calculate the lowest allowable refrigerant pressure for any combination of operating conditions for maximize chiller energy savings and more stable and smooth control of refrigerant pressure, especially under varying load and condenser inlet temperatures.

Overview

- 50 to 125 tons per module, up to 6 modules

- Water cooled condenser or remote air cooled condenser models

- Modular design allows up to six multiple circuits to be linked together with a common control system

- Compact size with easy access to controls and components

- Rotary screw compressor with integral oil separator and filter

- Compressor unloading for capacity control

- Stainless steel brazed plate evaporator

- Electronic expansion valve

- EPA approved low GWP R-513A refrigerant

- NEMA-12 C-UL 508A listed and labeled control panel

- Alarm horn with silence button

Available Options

- Rotary non-fused disconnect switch

- Flange disconnect switch

- Condenser coil coating (remote air-cooled condenser chillers)

- Alarm horn stack light

- ModBUS RTU, BACnet or LonWorks communications port

- 5-year compressor parts warranty

Specifications

Brochures

Operation Manuals

Product Catalogs

Powerful integrated control for MX Series central chillers.

Specification Tables

| Model | MXW50 | MXW75 | MXW100 | MXW125 |

|---|---|---|---|---|

| Cooling Capacity¹ | 50 ton chiller | 69 ton chiller | 100 ton chiller | 122 ton chiller |

| Set Point Range (°F) | 20 to 75 | 20 to 75 | 20 to 75 | 20 to 75 |

| Compressor (qty) | 1 | 1 | 1 | 1 |

| Process Fluid In & Out (in) | 3 | 4 | 4 | 4 |

| Condenser Water In & Out (in) | 3 | 4 | 4 | 4 |

| Length (in) | 140 | 142 | 147 | 148 |

| Width (in) | 36 | 36 | 36 | 36 |

| Height (in) | 81 | 81 | 81 | 81 |

| Shipping Weight (lbs) | 2,965 | 3,915 | 4,315 | 5,020 |

| Operating Weight (lbs) | 3,145 | 4,095 | 4,575 | 5,330 |

¹Cooling capacity when cooling water with 50°F set point, 60°F return, 95°F condenser air, R134a refrigerant.

| Model | MXR50 | MXR75 | MXR100 | MXR125 |

|---|---|---|---|---|

| Cooling Capacity¹ | 50 ton chiller | 65 ton chiller | 93 ton chiller | 114 ton chiller |

| Set Point Range (°F) | 20 to 75 | 20 to 75 | 20 to 75 | 20 to 75 |

| Compressor (qty) | 1 | 1 | 1 | 1 |

| Process Fluid In & Out (in) | 3 | 4 | 4 | 4 |

| Liquid Line Connection (in) | 1 3/8 | 1 5/8 | 2 1/8 | 2 1/8 |

| Discharge Line Connection (in) | 2 1/8 | 2 5/8 | 2 5/8 | 3 1/8 |

| Length (in) | 134 | 137 | 137 | 137 |

| Width (in) | 36 | 36 | 36 | 36 |

| Height (in) | 81 | 81 | 81 | 81 |

| Shipping Weight (lbs) | 2,495 | 3,340 | 3,485 | 3,700 |

| Operating Weight (lbs) | 2,620 | 3,510 | 3,710 | 3,980 |

¹Cooling capacity when cooling water with 50°F set point, 60°F return, 95°F condenser air, R134a refrigerant.

| Model | LAVF-14412 | LAVF-16410 | LAVF-24410 | LEVF-26410 |

|---|---|---|---|---|

| Chiller Used With | MXR50 | MXR75 | MXR100 | MXR125 |

| Number of Fans | 4 | 6 | 8 (2 rows of 4 fans) | 10 (2 rows of 5 fans) |

| Refrigerant Inlet Line (in) | 2 1/8 | 2 5/8 | 2 1/8 per row of fans | 2 1/8 per row of fans |

| Refrigerant Outlet Line (in) | 2 1/8 | 2 5/8 | 2 1/8 per row of fans | 2 1/8 per row of fans |

| Length (in) | 220 | 328 | 220 | 274 |

| Width (in) | 45 | 45 | 91 | 91 |

| Height (in) | 61 | 61 | 61 | 61 |

| Shipping Weight (lbs) | 1,600 | 2,810 | 2,851 | 4,046 |