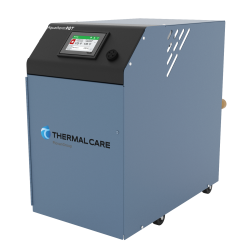

Positive/Negative Pressure Temperature Controller

Vactherm RVU Series

Vactherm RVU Series positive/negative temperature controllers eliminate downtime caused by a coolant leak in the mold or process water circuit. The unique design of the Vactherm allows the vacuum level to be adjusted to the exact amount necessary to stop the leakage, without drawing air into the water circuit. This provides better temperature control at lower flow rates than competitive designs. Plus units can run as nonferrous positive/negative temperature control systems even when no leak is present.

Overview

- 9 kW to 27 kW

- Automatic water make-up system for easy reservoir filling

- 3.5" touchscreen controller

- Stainless steel centrifugal pump protects against corrosion

- Built-in heat exchanger isolates the cooling source water from the mold water during cooling cycles

- Vacuum adjusting valve eliminates leaks without pulling air into the mold

- Dual low watt density, stainless steel sheathed heater elements provide long life and built-in standby

- Insulated 3.2 gallon (12 liter) stainless steel reservoir assures temperature stability and air separation

- Inlet strainer protects unit from debris in water

- Premium quality solenoid valves for automatic filling of tank and to regulate cooling in stainless steel heat exchanger

- Adjustable temperature deviation indicator (with audible alarm and silencer) permits user to set customized operating parameters

- Easily removable top/side panels make it simple to access interior components

- Four swivel casters make unit easy to move

Available Option

- Compound pressure/vacuum gauge and tee

Vactherm RVU Series - 360 Image

Specifications

Brochures

Operation Manuals

Vactherm RVU Series positive/negative temperature controller units includes a 3.5" touch screen and PLC controls.