60 to 800 Ton Accuchiller TC Series Central

Chiller

Single circuit up to 120 tons | Dual circuit up to 240 tons

Thermal Care is at the leading edge of process cooling technology. TC Series centrifugal compressor industrial central chillers use revolutionary, frictionless, magnetic bearing Turbocor compressors to deliver optimum chiller performance and part load efficiencies. This translates into the quietest, most reliable, and most energy efficient chillers ever built. Models are available with either single or completely independent dual refrigeration circuits.

Turbocor Compressor Cutaway

Overview

- Water cooled and remote condenser models available

- Advanced PLC System maintains stable and reliable operation of the chiller

- Stainless steel brazed plate evaporators for efficiency and corrosion resistance

- Energy-effficient, variable speed drive, Turbocor centrifugal compressor reduces operating costs vs conventional fixed-speed compressor technologies

- C-UL 508A listed and labeled industrial control panel

- Rotary circuit breakers for each compressor

- Single point connection for electrical hookup at control cabinet

- Only one major moving part - the compressor impeller which is used to compress gas and provides the highest full load efficiency. In addition, the Turbocor centrifugal compressor design operates at compression ratios as low as 1.2 (discharge pressure/suction pressure) compared to 1.8 or higher for other types of compressors. Lower compression ratios means less energy use.

- EPA approved low GWP R-513A refrigerant or energy efficient R-134a refrigerant

Oil Free Operation

- Eliminates oil management system and all related maintenance costs

- No potential oil contamination of refrigerant

- No compressor failure due to oil contamination

- Lower energy required can save up to 40% in annual operating costs when compared to screw-type compressor

Magnetic “Friction-Free” Bearings

- Equipment life is extended since there is no contact with surfaces as the shaft rotates

- Compressor senses a power failure as a normal shutdown. Internal capacitors and rotational energy allow the motor to become a generator and provide a fail-safe shutdown.

- Compressor shaft rests on a graphite-lined touchdown bearing when not in operation

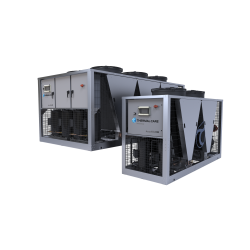

TCW Series - 360 Image

TCW Series Dual Circuit Chiller

Integrated Variable Speed Drive Motor Control

- Enhances temperature control capability for partial load performance

- Soft-start control reduces peak energy demand and extends motor life by lowering initial current inrush at start-up

- Lowest noise level; whisper quiet sound levels with 74 dBA (per compressor) and virtually no structure-born vibration

Integrated PLC Control

- Adaptive control maximize operational performance

- Provides extensive sensing capabilities and monitors compressor bearing and shaft positions six million times per minute

- Communications package allows for remote diagnostics of the chiller

- Built-in 24 VDC control circuitry

Specifications

Brochures

Operation Manuals

Product Catalog

A powerful PLC control system monitors, controls, and maintains stable and reliable chiller performance.

Specification Tables

| Model | TCW300C | TCW300E | TCW300J | TCW300M | TCW350Q | TCW350S |

|---|---|---|---|---|---|---|

| Cooling Capacity Range (ton)¹ | 30 to 90 ton chiller | 30 to 90 ton chiller | 30 to 90 ton chiller | 30 to 90 ton chiller | 40 to 120 ton chiller | 40 to 120 ton chiller |

| Set Point Range (°F) | 40 to 75 | 40 to 75 | 40 to 75 | 40 to 75 | 40 to 75 | 40 to 75 |

| Compressor (qty) | 1 | 1 | 1 | 1 | 1 | 1 |

| Condenser Water Inlet & Outlet Flange (in) | 4 | 4 | 4 | 4 | 4 | 4 |

| Process Fluid Inlet & Outlet Flange (in) | 3 | 3 | 4 | 4 | 4 | 4 |

| Length (in) | 118 | 118 | 120 | 120 | 141 | 145 |

| Width (in) | 29 | 29 | 29 | 29 | 37 | 37 |

| Height (in) | 77 | 77 | 77 | 77 | 75 | 75 |

| Shipping Weight (lbs) | 1,800 | 1,900 | 2,100 | 2,400 | 2,774 | 2,825 |

| Operating Weight (lbs) | 2,000 | 2,100 | 2,300 | 2,600 | 3,071 | 3,208 |

¹Cooling capacity when cooling water with 50°F set point, 60°F return, and 85°F condenser water, R134a refrigerant.

| Model | TCW600C | TCW600E | TCW600J | TCW600M | TCW700Q | TCW700S |

|---|---|---|---|---|---|---|

| Cooling Capacity Range (ton)¹ | 30 to 180 ton chiller | 30 to 180 ton chiller | 30 to 180 ton chiller | 30 to 180 ton chiller | 40 to 240 ton chiller | 40 to 240 ton chiller |

| Set Point Range (°F) | 40 to 75 | 40 to 75 | 40 to 75 | 40 to 75 | 40 to 75 | 40 to 75 |

| Compressor (qty) | 2 | 2 | 2 | 2 | 2 | 2 |

|

Condenser Water Inlet & Outlet Flange (in) |

6 | 6 | 6 | 6 | 6 | 6 |

| Process Water Inlet & Outlet Flange (in) | 4 | 4 | 6 | 6 | 6 | 6 |

| Length (in) | 124 | 124 | 124 | 126 | 139 | 164 |

| Width (in) | 54 | 54 | 54 | 54 | 73 | 73 |

| Height (in) | 77 | 77 | 77 | 77 | 63 | 63 |

| Shipping Weight (lbs) | 3,700 | 3,800 | 4,100 | 4,700 | 5,548 | 5,650 |

| Operating Weight (lbs) | 4,000 | 4,200 | 4,600 | 5,200 | 6,588 | 6,863 |

¹Cooling capacity when cooling water with 50°F set point, 60°F return, and 85°F condenser water., R134a refrigerant.

| Model | TCR300C | TCR300D | TCR300H | TCR350K | TCR350Q | TCR350S |

|---|---|---|---|---|---|---|

| Cooling Capacity Range (ton)¹ | 30 to 80 ton chiller | 30 to 80 ton chiller | 30 to 180 ton chiller | 40 to 120 ton chiller | 40 to 120 ton chiller | 40 to120 ton chiller |

| Set Point Range (°F) | 45 to 75 | 45 to 75 | 45 to 75 | 45 to 75 | 45 to 75 | 45 to 75 |

| Compressor (qty) | 1 | 1 | 1 | 1 | 1 | 1 |

| Refrigerant Liquid Line (in) | 1 3/8 | 1 3/8 | 1 5/8 | 1 5/8 | 2 1/8 | 2 1/8 |

| Refrigerant Discharge Line (in) | 2 1/8 | 2 1/8 | 2 5/8 | 2 5/8 | 3 1/8 | 3 1/8 |

| Process Water Inlet & Outlet Flange (in) | 3 | 3 | 4 | 4 | 4 | 4 |

| Length (in) | 105 | 105 | 109 | 109 | 129 | 129 |

| Width (in) | 29 | 29 | 29 | 29 | 37 | 37 |

| Height (in) | 77 | 77 | 77 | 77 | 75 | 75 |

| Shipping Weight (lbs) | 1,800 | 1,900 | 2,100 | 2,400 | 2,067 | 2,129 |

| Operating Weight (lbs) | 2,000 | 2,100 | 2,300 | 2,600 | 2,176 | 2,286 |

¹Cooling capacity when cooling water with 50°F set point, 60°F return, and 95°F condenser water, R134a refrigerant

| Model | TCR600C | TCR600D | TCR600H | TCR700K | TCR700Q | TCR700S |

|---|---|---|---|---|---|---|

| Cooling Capacity Range (ton)¹ | 30 to 160 ton chiller | 30 to 160 ton chiller | 30 to 160 ton chiller | 40 to 240 ton chiller | 40 to 240 ton chiller | 40 to 240 ton chiller |

| Set Point Range (°F) | 45 to 75 | 45 to 75 | 45 to 75 | 45 to 75 | 45 to 75 | 45 to 75 |

| Compressor (qty) | 2 | 2 | 2 | 2 | 2 | 2 |

| Refrigerant Liquid Line Per Circuit (in) | 1 3/8 | 1 3/8 | 1 5/8 | 1 5/8 | 2 1/8 | 2 1/8 |

| Refrigerant Discharge Line Per Circuit(in) | 2 1/8 | 2 1/8 | 2 5/8 | 2 5/8 | 3 1/8 | 3 1/8 |

| Process Water Inlet & Outlet Flange (in) | 4 | 4 | 6 | 6 | 6 | 6 |

| Length (in) | 112 | 112 | 120 | 120 | 139 | 145 |

| Width (in) | 56 | 56 | 56 | 56 | 73 | 73 |

| Height (in) | 77 | 77 | 77 | 77 | 63 | 63 |

| Shipping Weight (lbs) | 3,700 | 3,800 | 4,100 | 4,700 | 4,134 | 4,258 |

| Operating Weight (lbs) | 4,000 | 4,200 | 4,600 | 5,200 | 4,526 | 4,746 |

¹Cooling capacity when cooling water with 50°F set point, 60°F return, and 95°F condenser water, R134a refrigerant.

| Model | TCR600C | TCR600D | TCR600H | TCR700K | TCR700Q | TCR700S |

|---|---|---|---|---|---|---|

| Cooling Capacity Range (ton)¹ | 30 to 160 ton chiller | 30 to 160 ton chiller | 30 to 160 ton chiller | 40 to 240 ton chiller | 40 to 240 ton chiller | 40 to 240 ton chiller |

| Set Point Range (°F) | 45 to 75 | 45 to 75 | 45 to 75 | 45 to 75 | 45 to 75 | 45 to 75 |

| Compressor (qty) | 2 | 2 | 2 | 2 | 2 | 2 |

| Refrigerant Liquid Line Per Circuit (in) | 1 3/8 | 1 3/8 | 1 5/8 | 1 5/8 | 2 1/8 | 2 1/8 |

| Refrigerant Discharge Line Per Circuit(in) | 2 1/8 | 2 1/8 | 2 5/8 | 2 5/8 | 3 1/8 | 3 1/8 |

| Process Water Inlet & Outlet Flange (in) | 4 | 4 | 6 | 6 | 6 | 6 |

| Length (in) | 112 | 112 | 120 | 120 | 139 | 145 |

| Width (in) | 56 | 56 | 56 | 56 | 73 | 73 |

| Height (in) | 77 | 77 | 77 | 77 | 63 | 63 |

| Shipping Weight (lbs) | 3,700 | 3,800 | 4,100 | 4,700 | 4,134 | 4,258 |

| Operating Weight (lbs) | 4,000 | 4,200 | 4,600 | 5,200 | 4,526 | 4,746 |

¹Cooling capacity when cooling water with 50°F set point, 60°F return, and 95°F condenser water, R134a refrigerant.

Please answer the following four questions to estimate your annual energy savings by using a TC Series central chiller.

Based on the information you have provided, here is the estimated electrical cost of running a Thermal Care energy saving TC Series central chiller as compared with running a chiller with screw compressors, scroll compressors, or semi-hermetic compressors. Both air and water cooled models are shown.

Water Cooled

| TC Series Chiller | Screw Chiller | Scroll Chiller | Semi-Hermetic Chiller | |||

|---|---|---|---|---|---|---|

| Annual Cost | Percent Saved | Annual Cost | Percent Saved | Annual Cost | Percent Saved | |

Air Cooled

| TC Series Chiller | Screw Chiller | Scroll Chiller | Semi-Hermetic Chiller | |||

|---|---|---|---|---|---|---|

| Annual Cost | Percent Saved | Annual Cost | Percent Saved | Annual Cost | Percent Saved | |

In addition, the TC Series chiller qualifies for many available municipal energy rebates to dramatically increase your savings and reduce payback time. For an exact analysis of your situation and an in plant system evaluation, please submit your contact information using the Quick Contact form below, or give us a call at 847-966-2260.