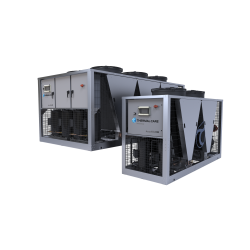

50 Ton & 100 Ton Centrifugal Compressor Chillers

TCFW375 - Single Circuit Chiller 50 ton (Ice Rink Chiller )

TCFW350 - Single Circuit Chiller 100 ton

Thermal Care has expanded its line of industrial TCF central chillers to include the TCFW375 ice rink chillers. TCF central chillers combine the efficiencies of both a hybrid film evaporator and a Turbocor variable speed centrifugal compressor to deliver optimum full and part load efficiencies. The result is one of the most energy efficient central chillers ever built.

Overview

- Water cooled single circuit model

- Advanced PLC System maintains stable and reliable operation of the chiller

- Hybrid film evaporator for the most efficient heat transfer

- Direct-drive variable-speed Turbocor centrifugal compressor technology continuously adjusts speed to match load and reduce operating costs

- C-UL 508A listed and labeled industrial control panel

- Rotary circuit breaker for compressor

- Single point connection for electrical hookup at control cabinet

- Only one major moving part - the compressor impeller which is used to compress gas and provides the highest full load efficiency and less energy use.

Integrated Variable Speed Drive Motor Control

- Enhances temperature control capability for partial load performance.

- Soft-start control reduces peak energy demand and extends motor life by lowering initial current inrush at start-up

- Lowest noise level; whisper quiet sound levels with 74 dBA and virtually no structure-born vibration

Magnetic “Friction-Free” Bearings

- Equipment life is extended since there is no contact with surfaces as the shaft rotates

-

Compressor

senses a power failure as a normal shutdown. Internal capacitors and rotational

energy allow the motor to become a generator and provide a fail-safe shutdown. - Compressor shaft rests on a graphite-lined touchdown bearing when not in operation

Oil Free Operation

- Eliminates oil management system and all related maintenance costs

- No potential oil contamination of refrigerant

- No compressor failure due to oil contamination

- Lower energy required can save up to 40% in annual operating costs when compared to screw-type compressor

Integrated TCF PLC Control

- Adaptive control maximizes operational performance

- Provides extensive sensing capabilities and monitors compressor bearing and shaft positions six million times per minute

- Communications package allows for remote diagnostics of the chiller

- Built-in 24 VDC control circuitry

TCFW375 Additional Features

- Modular expansion to over 300 tons using up to six chillers

- Unit has a slim footprint and can fit through a 34” opening

- Turbocor TTH375 highlift variable speed centrifugal compressor with oil-free, magnetic bearings is ideal for ice rinks

- R513A Class A refrigerant features low toxicity and low flammability

- Lower Global Warming Potential (GWP)* - Featuring OpteonTM XP10 (R-513A) Refrigerant

*In comparison to HCFC-22.

NHL and the NHL Shield are registered trademarks of the National Hockey League. ©NHL 2022. All rights reserved.

TCFW350 Additional Features

- Modular expansion to over 600 tons using up to six chillers

- EPA approved low GWP R-513A refrigerant or energy efficient R-134a refrigerant

TCFW350 - 360 Image

Specifications

Brochures

Operation Manuals

Product Catalog

A powerful PLC control system monitors, controls, and maintains stable and reliable chiller performance.

TCF Central Chiller with Turbocor Compressor & Hybrid Film Evaporator

TCFW375 50 Ton Water Cooled Ice Rink Chiller

Tabor Academy Installs TCFW375 with Opteon R-513A Refrigerant

Specification Tables

WATER COOLED CONDENSER SINGLE - CIRCUIT CHILLER GENERAL DATA

| Model | TCFW350A | TCFW375 |

|---|---|---|

| Cooling Capacity Range (ton) | 40 to 1201 | 45 to 552 |

| Refrigerant Type | R134A | R513A |

| Set Point Range (°F) | 40 to 75 | 10 to 55 |

| Intended Operating Range (°F) | 40 to 75 | 10 to 15 |

| Compressor (qty) | 1 | 1 |

| Process Fluid | Water | 40 % Ethylene Glycol |

| Evaporator Flow | 240 gpm @ 50°F | 467 gpm @ 10°F | 427gpm @ 15°F |

| Shipping Weight (lbs) | 3,400 | 6,000 |

| Operating Weight (lbs) | 3,800 | 5,600 |

| MCA @ 460/3/60 (amps)3 | 229 | 230 |

| MOP @ 460/3/60 (amps)4 | 400 | 400 |

¹Cooling capacity when cooling water with 50°F set point, 60°F return, and 85°F condenser water.

2Cooling capacity when cooling water with 13°F set point, 16°F return, and 85°F condenser water.

3MCA is Minimum Circuit Amps under full load, used for minimum wire size requirement.

4MOP is Maximum Overcurrent Protection, used for sizing main power protection device.

Energy Efficiency Comparison - TCFW350.

TCFW350 variable speed centrifugal compresssor chiller vs a typical flooded evaporator, fixed-speed screw compressor chiller.